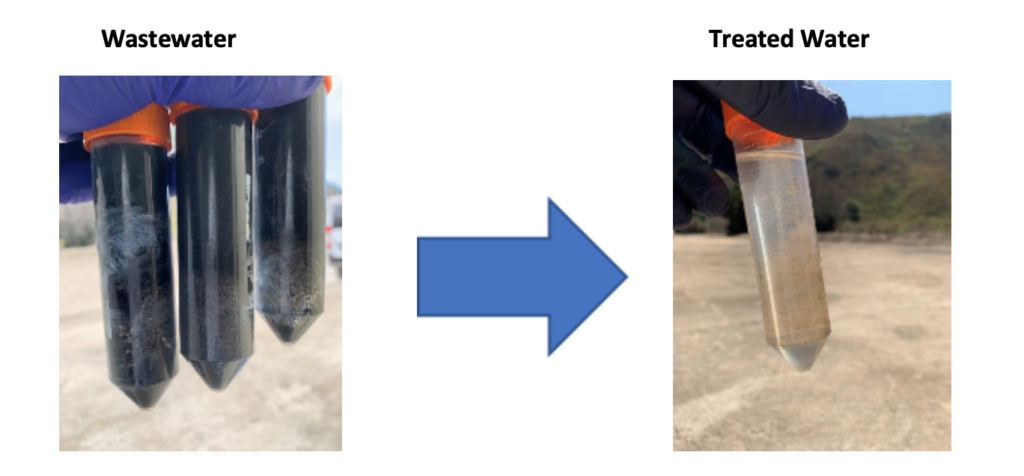

Project: Design, build and operate a high oil and suspended solids oilfield wastewater treatment process

Synopsis: Our client, a California-based oil producer, hired PWS to design, build and operate a 500 barrels per day treatment process to remove oil and suspended solids from oilfield wastewater including pigging, sand dumps and tank bottoms.

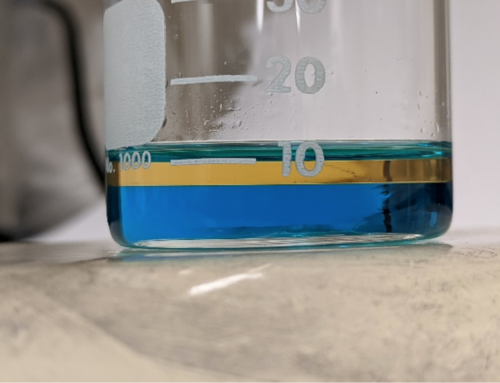

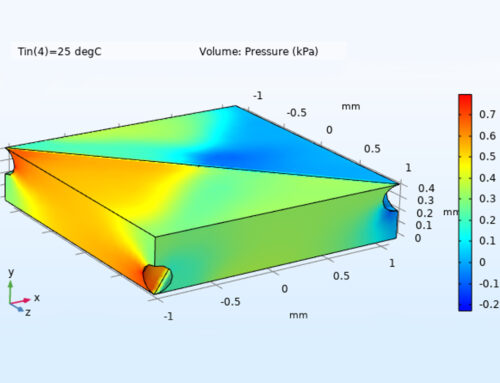

Solution: Chemical clarification following by filtration and solid waste minimization

Results: Over a course of 3 months, wastewater containing as much as 20 vol.% oil and 10 vol.% suspended solids was cleaned up to provide clarified water with turbidity and oil and grease contents of <50 NTU and <50 mg/L respectively, using a process train comprised of chemical/enhanced gravity separation followed by micro-filtration.