Project: Design, build and operate a high recovery reverse osmosis process for desalination of oilfield produced water

Synopsis: A California oil producer hired PWS to perform a two-month long field pilot test study performed to desalinated oilfield high TDS brackish produced water. The primary treatment objective was to meet the beneficial reuse standards required by the neighboring agricultural end-users, while the secondary objective was to maximize the RO process recovery and minimize RO brine volumes to reduce the cost of brine disposal.

The scope of work for the project was as follows:

- Initial treatability study to identify contaminants of concern and obtain the necessary data to design the process train

- Design, build, procure, install, commission and operate a process train at a 15-20 gallon per minute range

- Use the data from the pilot study towards a techno-economic analysis of the process at scale

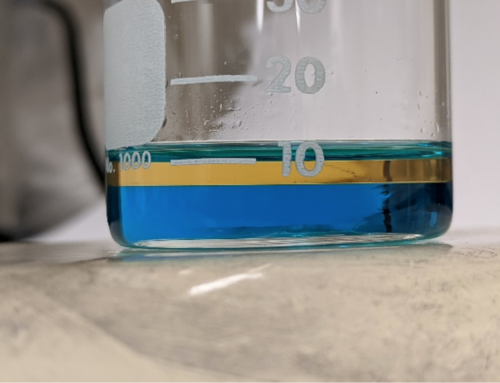

Pilot site feed produced water and treated water

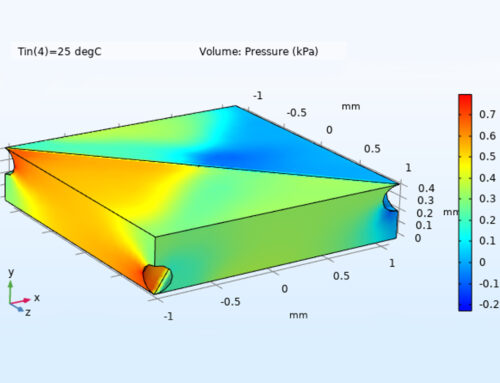

Solution: For membrane-based desalination to operate sustainably at this site, extensive care was given to the design of the pre-treatment. The main categories of contaminants that needed to be addressed were free oil and greases, suspended solids, dissolved organics and hydrocarbons, hardness and inorganic salts, and silica. Boron is another parameter that is universally present at potentially toxic levels in produced waters across California. In order to bring boron down to acceptable levels, consideration was given to boron chemistry and membrane rejection when designing the RO component of the process.

Consequently, a process train consisting of the following key unit operations was deployed:

• Free and suspended oil separator

• Chemical softening to remove excess harness

• Ultrafiltration to remove suspended solids

• Carbon media filtration to remove dissolved organics

• Two-stage RO to remove monovalent ions and boron

Results: Using data from the pilot, PWS developed an economic model that showed that the combined capital and operating cost of advanced treatment of high hardness, high TDS brackish produced water was within $0.56 for every 1000 gallons of the water treated. This provided an affordable option when considering all the regulatory, limited disposal infrastructure, and rising costs of water management such as transportation to other disposal sites.

Click here for more detail about the pilot data and overall technical and economic aspects of advanced produced water in California can be provided in one our recent publications.